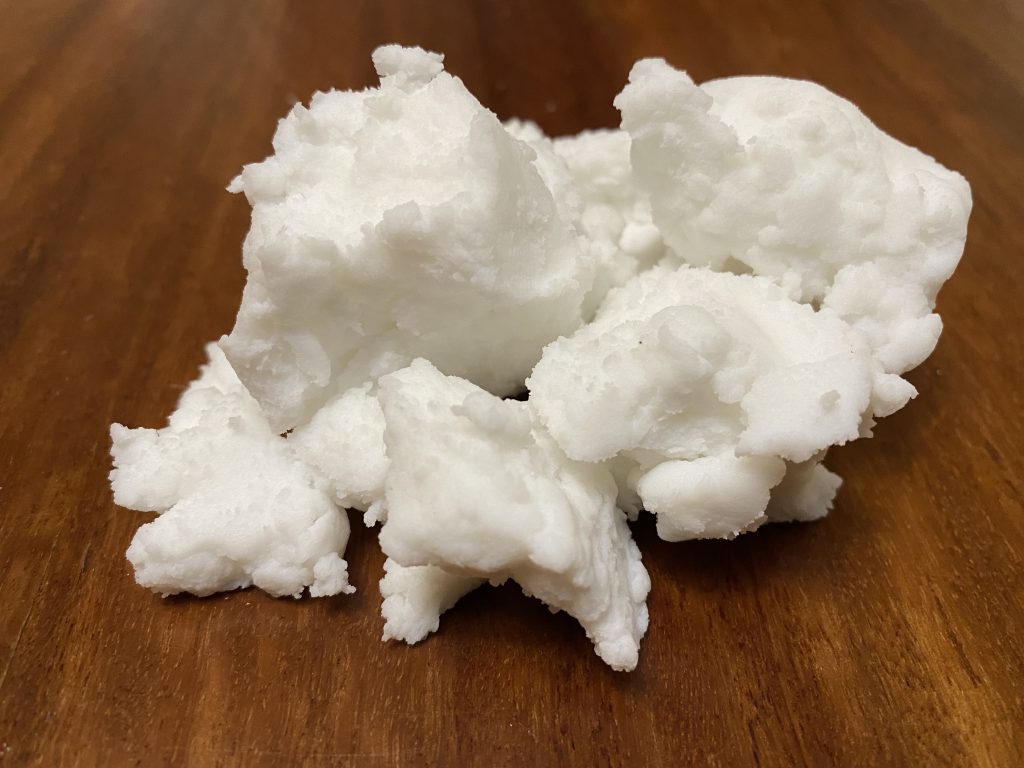

Microfibrillated cellulose (MFC)

MFC’s are naturally occurring nanocellulose polymers that are extracted from biological sources such as trees and other plants. MFC’s physical properties are increased tensile strength, an extremely high surface area and a large fluid holding capacity.

Kylarr Staple Fibres

Kylarr staple fibres are made from 100% wood-based MFC using 0% toxic chemicals in the dissolution process. As other processes use organic solvents and ionic liquids to dissolve cellulose, their high monetary and environmental cost impede their further large-scale applications.

Spinning Technology

With proprietary breakthrough advanced fibre spinning technology that using minimal chemicals, Kylarr fibres promise a cleaner future for the textile industry. It is believed that the commercial scale of a homogenous high strength fibre from low concentrations of dissolved nanocellulose will be achieved.

Kylarr Continuous Fibre

Kylarr fibres are made using minimal toxic chemicals and minimising waste while displaying properties desirable for a wide cross section of global industries including, but not limited to, the fashion, medical and absorbency markets.

Kylarr staple fibres, 40mm lengths.

Aussie Merino wool staple that has been flick carded to open ends and remove debris.

Blending the Kylarr and Merino fibres with hand cards.

Rolling the Rolag from the blended fibres.

35% Kylarr : 65% Merino blend carded into rolags ready for Woollen Longdraw spinning.

Single yarn being spun from the 35% Kylarr : 65% Merino blend.

Bobbin beginning to fill with newly plyed yarn.

First skein ever produced of 35% Kylarr : 65% Merino.

Sustainability

Kylarr fibres will satisfy the 2030 Agenda for Sustainable Development, goals 13-15, that aim to combat climate change and its impacts along with the conservation and sustainability of our ocean and terrestrial ecosystems.